- Visibility 301 Views

- Downloads 28 Downloads

- DOI 10.18231/j.ijmr.2022.030

-

CrossMark

- Citation

Food fuel and fermentation products

Introduction

Fermentation is the chemical process in which molecules like glucose are converted to ethanol and carbon di oxide in the absence of oxygen(anaerobic) by microorganisms like yeast, fungi and bacteria. In other words, fermentation is a process that produces chemical changes in organic substrates through the action of enzymes following different metabolic pathways producing favourable end products by microorganisms. Fermentation of wine and beer and dairy products and baking flour are known to mankind from very old times like 10000 years ago.

Fermentation technology has grown manifolds in recent years other than food and dairy products, in the commercial production of organic acids like lactic acid, acetic acid, citric acid, butyric acid, ethanol, butanol, acetone, vitamins, antibiotics, enzymes. Electro fermentation is an up growing technology that can overcome the limitations of conventional fermentation. Recently, Electro fermentation utilises microbial fermentative metabolism with electrodes involving electrochemical process to produce fermentation products like ethanol, butanol, organic acids, vitamins, antibiotics with efficient usage of substrates and organic wastes rich in carbon, yielding enhanced production of end products.

Fermentation of South Indian Foods

Reddy et al.,(1982) [1] Idly and dosa are made of black gram (Phaseolus mungo.L) and rice (Oryza sativa).In the batter, microorganisms involved in fermentation are yeasts, hetero fermentative Lactic acid bacteria, Leuconostoc mesenteroides, Streptococcus faecalis, pediococcus cervisae. Blackgram serves as the ample fermentation medium. The protein content, B vitamins, nutrients, texture and flavour are enhanced after fermentation of the batter. Chelliah et al.,(2017)[2] in their study added 10% finger millet,10% pearl millet flour to the normal idly batter and found increased nutrient content in the batter like soluble fibre, calcium, iron after fermentation which is relevant for diabetic patients. Compared to 12h fermentation period of normal idly batter, it took only 6hr time for finger millet and 8hr time for pearl millet to attain the desirable texture. Apart from improvising nutritional qualities, decrease in fermentation time is more suitable for commercial preparation.[3] Studied co-fermentation of finger millet with horse gram to produce high protein breakfast dosa. They observed increase in protein and essential amino acids like Lysine in the batter. Hence to eradicate malnutrition in children this combination of millets in dosa batter can be an efficient method.

Biopreservation and Enhanced Taste of Food Products by Fermentation

Ito et al.,(2021) [4] Soy sauce is a traditional Japanese condiment produced from the fermentation of soybeans, wheat, and salt by microorganisms koji molds, halophilic lactic acid bacteria, and salt-tolerant yeast. Enzymes produced by koji molds breakdown or hydrolyse protein and starch in the raw materials in to aminoacids and sugar which are further converted into organic acids and aromatic products by yeast and lactic acid bacteria. These final products increases the flavour, aroma and shelf life of the food product. [5] Kenaf seeds are ground to powder and its protein extracts was fermented with Lactobacillus casei for 72 h at 37 °C, which improved the bioactive peptide compounds. The fermented protein had high antibacterial activity and inhibited pathogens Salmonella typhimurim, Escherichia coli, Pseudomonas aeruginosa, Staphylococcus aureus, Bacillus subtilis, and Streptococcus pyogenes thus qualifying itself as a natural preservative for food products.[6] Biopreservation of food products by Bacteriocin from lactic acid bacteria (probiotics)is more effective in controlling pathogens spoiling food without affecting the intrinsic properties of the food product. Compared to chemical preservatives these natural preservatives are cheap and highly effective in pathogen control with no side effects increasing the shelf life of the food product. In this study, Enterococcus sp. which is a GRAS (generally regarded as safe) level LAB that produces antimicrobial agent- bacteriocin namely enterocin is used in the biopreservation of meat. The most common bacteriocins used in biopreservation are sakacin, leucocin, pediocin, nisin, enterocin A&B, As-48 inhibiting the growth of L. monocytogenes and other pathogenic bacteria Salmonella, E.coli, Listeria spp, L. sakei.

Anti Oxidants Obtained by Fermentation

Martiquijal, Francisco et al.,(2021)[7] Solid state fermentation is efficient in production of antioxidants and preservatives from industrial food waste. Organisms like Saccharomyces cerevisiae, Aspergillus sp., Bacillus subtilis can be used to produce phenols and flavonoids, anti oxidant peptides, coumaric acid, caffeic acid, cinnamic acid, ferulic acid…Dufresne et al(2000)[8] Kombucha is a fermented tea extract supplemented with sucrose and fermented with yeasts and acetic-acid bacteria. The main acetic acid bacteria found in Kombucha are: Acetobacter xylinum, A. xylinoides, Bacterium gluconicum, A. aceti, A. pasteurianus and yeast species are Schizo saccharomyces pombe, Saccharomycodes ludwigii, Kloeckera apiculata, Saccharomyces cerevisiae, Zygo saccharomyces bailii, Brettanomyces bruxellensis, B. lambicus, B. custersii, Candida and Pichia species. It is reported that tea polyphenolics inhibit alpha-amylase activity in saliva, reduce the intestinal amylase activity which in turn lowers the hydrolysis of starch to glucose and reduces glucose assimilation and hence results in weight loss and prevents diabetes and controls sugar level to certain extent. Fermented Tea contains Flavonols, mainly quercetin, kaempferol, myricetin, and their glycosides which have a number of health benefits. Flavanols and polyphenols are anti oxidants that can balance harmful free radicals thus causing prevention and resistance to cancer.

Vitamins Production

Vitamins are organic compounds that are needed in small quantities required for normal growth and metabolism and their deficiency causes disorders and diseases. Vitamins Bcomplex, Vitamin C are water soluble and A,D,E,K are fat soluble. There are 8 types of B vitamins that are collectively called B complex, They are Thiamin (vitamin B1), riboflavin(vitamin B2), niacin(vitamin B3), pantothenic acid(B5), pyridoxine, (vitamin B6), biotin(vitamin B7), folate and folic acid(B9), Cobalamin,(vitamin B12).[9] Riboflavin is a vital B vitamin rich in dairy products, green vegetables, eggs and meat. The recommended dosage per day is 1.3 milli grams. Riboflavin deficiency can cause impaired vision, reduced growth, cardiac risk, changes in cerebral glucose metabolism liver and skin damage. Lactic acid bacteria are nowadays used as in situ fortifying agents for riboflavin production. Some of the LAB organisms involved in riboflavin biosynthesis are Lactococcus lactis, Lacto bacillus delbrueckii, Lactobacillus plantarum, Listeria monocytogenes, L.fermentum, L.acidophilus and Streptococcus pyogenes. Riboflavin overproduction can be achieved by chemical analogues method and genetic engineering.[10] Riboflavin is the precursor of flavin mononucleotide and flavin adenine dinucleotide coenzymes crucial for the production of energy in cellular respiration. Microbial biosynthesis of riboflavin by using renewable raw materials reduces the cost and makes the fermentation by Bacillus subtilis species more efficient and economical way of production.

Industrial Enzymes Produced by Fermentation

Thomas et al.,(2013)[11] There are more than hundred enzymes produced by solid state fermentation from various substrates. A few examples are Lipase, Xylanase, Laccase, Chitosanase, Cellulase, Chitinase, Amylase, Protease Leather market consumed highest amount of enzymes followed by bioethanol market. The food and beverage enzymes market value was 1.3 billion dollars in 2015 with an annual growth of 5.1%. Different enzymes are produced by different micro organisms under optimised conditions.

Enzyme lipase

Lipase is an enzyme that hydrolyses fats into fatty acids and glycerol.[12] studied Lipase production by Serratia marcescens ECU1010 in cloud point system. Extractive microbial fermentation in cloud point system showed positive results for lipase production thereby adding evidence to potential production of enzymes and proteins in large scale by this method.[13] chose alkalophilic bacterial strain (Bacillus sp. KS4) with maximum lipase activity of 0.612 U/ml. They implemented optimisation parameters like 1.16% olive oil, 0.12% tween 80, 5.99 mM MgCl2, and 7.16% inoculum size to obtain lipase 2.17 U/ml enhanced from initial 0.612U/ml. Joseph et al.,(2006)[14] Staphylococcus epidermidis isolated from spoiled frozen marine fish samples produced enzyme lipase of 8.1 U within 72 h in batch fermentation. On addition of tributyrin, sodium chloride, lactose increased lipase production. Apart from optimisation of physical factors, immobilisation of cells of S. epidermidis was found to increase the lipase production manifolds making this method fit for commercial production.[15] The authors used a valid model of response surface methodology and produced lipase 265U/ml by Bacillus aryabhattai SE3-PB strain under optimised conditions.[16] Pseudomonas aeruginosa KM110 isolated from industrial effluents produced a potential alkaline lipase enzyme that was stable under pH 7-10 and found stable towards many metal ions and detergents.

Enzyme cellulase

Sadhu et al.,(2013)[17] Cellulase is the enzyme needed for breaking down of complex ligno cellulose biomass into simple sugars. Out of the global industrial enzyme demands, cellulase contributes to 8%. Though fungi are effective cellulase producers, recently novel cellulase producing bacteria are exploited for their extreme stress tolerance behaviour. Bacteria that synthesize the complete enzyme system that results in complete hydrolysis of the crystalline cellulose are called “true cellulolytic “bacteria. Bacteria that produce partly endoglucanases and ß-glucosidases, but not the complete system, are called “pseudo cellulolytic”. Thermo anaerobium sp, Clostridium sp, Ruminococcus sp, numerous Bacillus sp., Pseudomonas fluorescens, Zymomonas mobilis have cellulase producing ability. Solid state fermentation method requires less moisture content and energy and end products are received in more concentrated form. This method is applicable in solid substrates like bagasse, corn and wheat stalk, paddy straw, bran, crop residues, biowaste from agricultural products. Submerged fermentation uses liquid broth, molasses, corn steep liquor as substrates which involves bacteria that need high moisture content. The purification of end products is easier in this method.[18] Many chemical processes are replaced by enzyme treatment as they are environment friendly. In food processing industry, enzymes cellulase, xylanase, pectinase are of importance in extracting fruit and vegetable juices. Their use decreases the viscosity of nectar and purees from fruits and increases the stability, aroma and flavour of the fruit juices. In textiles, cellulases are used to give stone wash look in jeans and biopolishing of cotton fabrics. They are added in detergents to decrease discolouration due to repeated washes of clothes. In paper and pulp industry, cellulase is used to condition the fiber and increase brightness by bioleaching. In ethanol production cellulase is used for saccharification of polysaccharides from lignocellulose biomass. Waghmare et al.,(2018)[19] isolated a cellulolytic enzyme Enterobacter sp. SUK-Bio from plant litter soil. This isolate was used on substrates like carboxy methyl cellulose, sugarcane trash, grass powder, sorghum husk, wheat straw and water hyacinth. Sorghum husk produced maximum enzymes after 8 days of incubation like β-glucosidase (37.10 U/mL), glucoamylase (33.26 U/mL), xylanase (26.26 U/mL), endoglucanase (12.24 U/mL), exoglucanase (2.52 U/mL), filter paperase (0.15 U/mL).

Enzyme amylase

Gopinath et al.,(2017)[20] in this review collectively recalls numerous bacterial species producing amylase enzyme which breaks down starch in to simple sugars. Due to this property they are used in fruit juices and beverages industry, food industry, paper and textile industry. Most of the Bacillus species are amylase producers that include Bacillus subtilis, B. vulgaris, B. megaterium, B. cereus, B. halodurans B. stearothermophilus, B. amyloliquefaciens, B. licheniformis, B. coagulans, B. polymyxa, B. mesentericus, and Bacillus sp. Ferdowsicous, halophilic strain Bacillus dipsosauri and LAB like Lactobacillus fermentum, Lactobacillus manihotivorans. Das et al.,(2015)[21] identified a new B. subtilis BI19 from the soil samples collected from Savar, Dhaka to be potential producers of amylase enzyme economically. By employing zone clearing technique on starch agar plate (1% starch in nutrient agar) with flooded iodine, screening for amylase producers are done and pure cultures are isolated by using 16S rDNA and Blast search the new Bacillus strain is confirmed. Sundar Ram et al.,(2014)[17] in their review discusses in detail about industrial applications of amylase. In bakery industry by improving texture of the dough by converting starch in to fermentable sugars; In detergents by converting starch in to soluble dextrin; In food industry by converting starch in to glucose and fructose syrup; In the pre treatment of alcohol production from starch by converting in to easily fermentable sugars; To make less viscous starch suitable for coating in paper; In textiles as a desizing agent to remove applied starch on the woven fabric.

Fermentation of Sea Weeds

Chirapart, Anong et al.,(2014)[22] Thai sea weeds are pretreated by hydrochloric acid hydrolysis The organisms of the study are red algae Gracilaria salicornia and Gracilaria tenuistipitata and green algae Ulva intestinalis and Rhizoclonium riparium. S.cerevisiae is the fermenting agent used to obtain maximum ethanol from Thai seaweeds.[23] Anaerobic digestion (AD) of brown algae Laminaria japonica was used in methane and biogas production which is further used in heat production and electricity generation. About 20% of the electricity produced in the plant is utilised to meet the total energy demands of the plant and the digester. The digestate which is of fertiliser value can earn revenues of 2-3 million dollars per year which economises the process. The production process is sustainable as it meets the energy requirements without fossil fuels. Thus electricity production from brown algae is self sufficient and an economical process leading us to sustainable development.

Electro Fermentation of Carbon Di Oxide and Organic Wastes

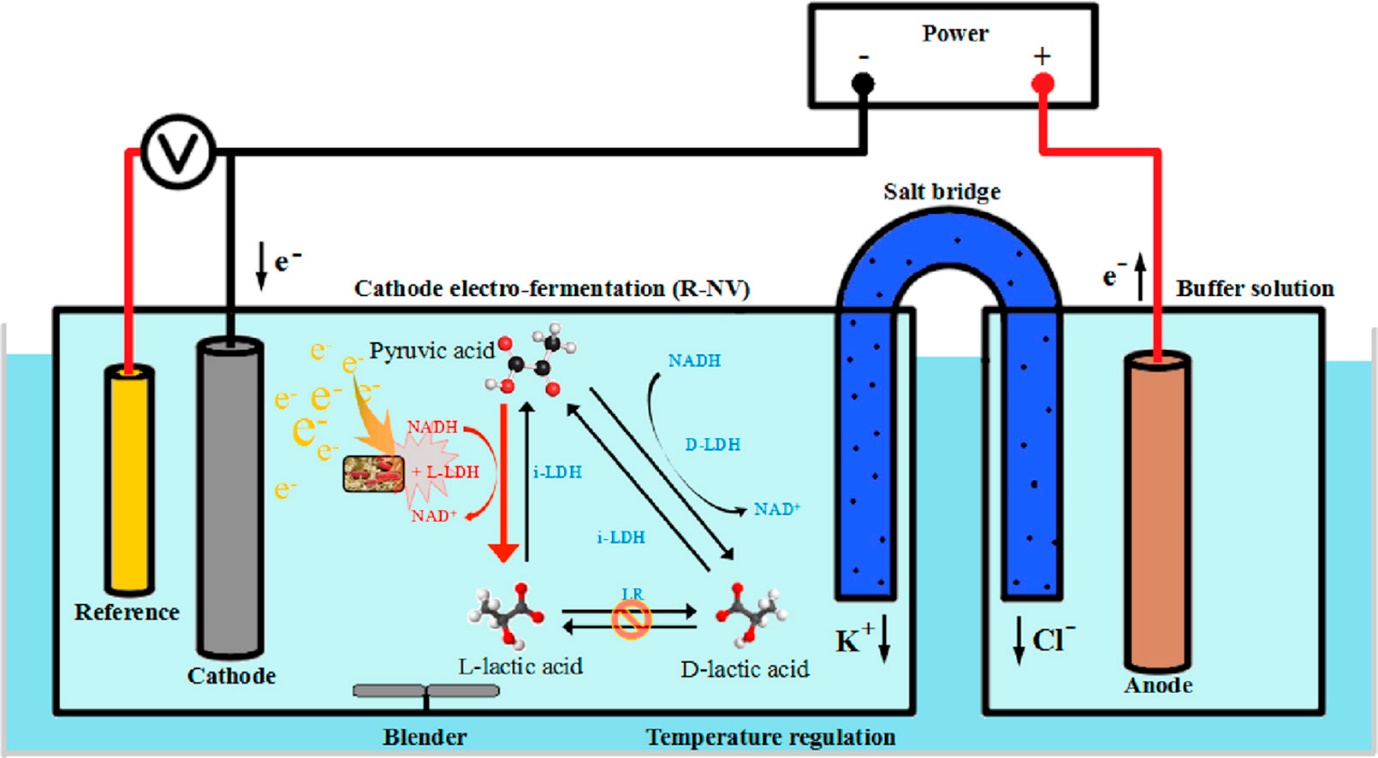

Electro-fermentation (EF) is a novel process that consists of electrochemically controlled microbial fermentative metabolism with electrodes. The electrodes can act as either electron sinks or sources that allow unbalanced fermentation. It involves interactions between microorganisms and the surface of the electrodes through cellular mechanisms of extracellular electron transfer. Choi et al.,(2012)[24] used Clostridium tyrobutyricum to produce butyrate from sucrose using Electro fermentation method(EF) and obtained 30% increased yield of butyrate than conventional methods. Choi et al.,(2014)[25] used Clostridium pasteurianum to produce butanol from glucose and observed three fold increase in butanol yield using EF.

Jiang, Yong et al.,(2019)[26] in their review discusses in detail about valorisation of organic wastes by electro fermentation to yield by products like methane, organic acids like lactic acid, butyric acid, alcohols like methanol, ethanol, butanol and organic compounds like formic acid, propionic acid, caproic acid and medium chain fatty acids, poly hydroxy alkanoates and alkyl esters. Several organisms capable of electrosynthesis are Sporomusa ovata, Sporomusa sphaeriodes, Sporomusa silvacetica, Clostridium ljungdahlii, Methanobacterium sp., Clostridium aceticum, and Moorella thermoacetica and engineered GMOs also. The main principle involved in this EF process is autotrophic microorganisms use a solid electrode (cathode) as the electron donor and soluble CO2 as the electron acceptor converting organic waste into useful end products. The oxidation reduction potential and extra cellular and intra cellular electron transfer are modified during the metabolism.

Anaerobic Fermentation of Glycerol

Yazdani et al.,(2007)[27] Species like Klebsiella, Citrobacter, Enterobacter sp., Clostridium, Lactobacillus and Bacillus are the common organisms that can ferment Glycerol. Genetically engineered Escherichia coli can also ferment Glycerol in an efficient manner. By- products like succinic acid, ethanol-formate, ethanol-hydrogen, acetic acid,.. are obtained at higher yields from glycerol than from simple sugars like glucose. Gallardo et al.,(2014)[28] Crude glycerol present surplus in waste products of biodiesel production is taken for this study to produce n-butanol and 1,3-propanediol (1,3-PDO) by Clostridium pasteurianum DSM 525 fermentation. By supplementing the culture medium with sodium butyrate and increasing the feed glycerol concentration, Butanol production is increased compared to 1,3 propane diol.

ABE Products

Kujawska et al.,(2015)[29] Butanol can be obtained from fermentation by Bacteria Clostridium species. The most important species are Clostridium acetobutylicum, Clostridium saccharobutylicum, Clostridium beijerinckii and Clostridium saccharo perbutyl acetonicum. Acetone, n-butanol and ethanol(ABE) metabolism involves fermentation of ligno cellulose biomass and other substrates by Clostridium species. ABE can be recovered from fermentation broth by several techniques like distillation, adsorption, freeze crystallization, gas stripping, liquid–liquid extraction, pertraction, reverse osmosis, membrane distillation, thermos pervaporation, sweeping gas pervaporation and vacuum pervaporation.[30] The recovery of ABE products from fermentation broth requires large energy consumption which is quite expensive. Flash fermentation is an economical technique which is a type of continuous fermentation system with integrated product recovery. The bioreactor is working at atmospheric pressure and the broth is heated at 37degrees which is circulated in a closed loop to a vaccum chamber. High yield of butanol is recovered by condensation of the broth in this method.[31] The seeds of seagrass Zostera marina have 83.5% carbohydrates which is comparable to carbs in wheat and corn. This is used as substrate for fermentation after treating with glucoamylase (50°C, 96 h).With Saccharomyces cerevisiae strains NBRC10217 as fermenting organism, ethanol yield of 65g/l in monographic double fermentation method and 130g/l in parallel double-fermentation method is obtained.

Pratto, Bruna, et al.,(2020)[32] 5.7% w/w ethanol concentration yielding 290 L of ethanol per ton of pretreated sugarcane straw within 45 h of total processing time was obtained. The study involved solid state fermentation process by Saccharomyces cerevisiae on hydrolysed and enzymatic saccharified sugarcane straw biomass.

N-caproic Acid Production

DeAraujo Cavalcante, Willame, et al.,(2017)[33] Caproic acid has ten times higher fuel value than ethanol. Caproic acid can be produced through elongation of acetic acid, lactic acid in anaerobic bioreactors using open cultures of organisms like Clostridium kluyveri, Clostridium sp. BS-1 and Megasphaera elsdeni. Caproic acid can be used as antimicrobial agent, flavor additive, additive in animal feed, and feedstock for biofuel and chemical industries.[34] Clostridium cluster IV of the family of Ruminococcaceae strain CPB6 produced 16.6 g/L Caproic acid (from 45.1 g/L lactate) with a maximum productivity of 5.29 g/L/day.[35] For this study the authors used lactic acid and ethanol as substrates for production of caproic acid. They found results as lactic acid was better yielding than ethanol which yielded 20%low by chain elongation process.

Production of Acetic Acid & Vinegar

Bhat et al.,(2014)[36] Vinegar is a french word means as sour wine which contains 5% acetic acid in water and other ingredients. Vinegar is a sour liquid used as a condiment and food preservative obtained by aerobic processing of wine or ethanol that adds aroma and flavour to the food item. The old traditional Orleans method is the best way to get pure vinegar. Acetobacter is the microorganism that converts ethanol into acetic acid aerobically by the action of enzymes.[37] The history of Vinegar started to flourish from Pasteur in1864 who claimed that biotransformation of wine into vinegar was caused by veil of Mycoderma aceti on its surface. Species of the genus Acetobacter are the dominating vinegar producers. The most common organisms are A. pasteurianus, A. malorum, A. cerevisiae, and A. aceti. Other than acetobacter, some organisms producing vinegar areKomagataeibacter europaeus and Gluconacetobacter intermedius. In submerged fermentation,oxygen availability is a controlling factor for flavonol content present in vinegar. High quality vinegar often contains compounds like vanillin, benzaldehyde and eugenol that attributes to the pungent feel in vinegar taste.

Biogenic H2S & Nano Magnetite Mineral

Li, Yi-Liang, et al.(2006)[38] Ferrihydrite, goethite, and magnetite and Hematite are reduced to iron sulphide by SRB Desulphovibrio desulphuricans strain G-20 in the presence of sulphate due to biogenic Hydrogen sulphide. But in the absence of sulphate, instead of iron sulphide, Iron phosphate mineral is formed. There are previous literature giving evidence for carbonate sedimentation in microbial mats due to anaerobic respiration by SRB. The importance of SRB in mineral recycling of geochemical cycles still remains a puzzle.[39] X-ray diffraction and TEM studies reveal the transformation of nano maghemite to nano magnetite by SRB through solid phase Iron(III) reduction. In natural environment these two minerals act as energy sources for SRB growth. The role of SRB and magnetite mineral produced by SRB in Parkinson’s disease is also a puzzle to be solved.[40] Sulfate-reducing bacterium Archaeoglobus fulgidus produced magnetic precipitate containing mineral magnetite. The results were obtained by Mossbauer spectroscopy analysis in this study.[41] Adsorption of hydrogen sulphide by Platinum metal was studied by the author. Heating platinum to high temperature 100 deg.c made it an efficient catalyst for decomposition of hydrogen sulphide into hydrogen gas and sulphur.[42] Hydrogen sulphide is a highly polluting gas due to its corrosive nature. It can be converted into high economic value feedstock if hydrogen and sulphur can be separated. Conventional catalytic reactors are coupled with Membrane separators(CR/MS) for the efficient feed conversion in Open reactor architecture (OA). This design allows the silica membranes to perform hydrogen separation at a low temperature 600 deg .c compared to 900 deg.c working temperature of catalytic reactors alone.[43] The authors made many combinations of photo catalysts for the splitting of hydrogen sulphide into hydrogen which is the promising future fuel. Out of those RuO2/CuGa1.6Fe0.4O4 photocatalyst produced maximum yield of 8370 µmol/h of hydrogen.

Conclusion & Future Aspects

From this study, it is clear that fermentation products are very relevant to us, and they are sort of renewable energy. We have to exploit the microbial biodiversity to their full capacity to extract their potential. Till the day of biogeochemical cycles existing on this mighty earth, fermentation by micro organisms will continue to exist and render us useful products. This study can be further extended vastly to biofertiliser and biopesticides production, Single cell protein and aminoacid production, vaccines, hormones, antibiotics production, Biopolymer and EPS production, Biosurfactants and bacterial metabolites production that can yield fruits of fermentation mechanism infinitely. The highlight of this study is Biohydrogen production which is the cleanest energy that is going to serve the energy sector as next generation fuel. This review can be remembered as FFF-3F’s (Food, Fuel, Fermentation).

Source of Funding

None.

Conflict of Interest

None.

References

- NR Reddy, MD Pierson, S Sathe, K Salunkhe. Idli, an Indian fermented food: A review. J Food Qual 1982. [Google Scholar]

- R Chelliah, SR Ramakrishnan, D Premkumar, U Antony. Accelerated fermentation of Idli batter using Eleusine coracana and Pennisetum glaucum. J Food Sci Technol 2017. [Google Scholar]

- BD Palanisamy, V Rajendran, S Sathyaseelan, R Bhat, BP Venkatesan. Enhancement of nutritional value of finger millet-based food (Indian dosa) by co-fermentation with horse gram flour. Int J Food Sci Nutr 2012. [Google Scholar]

- K Ito, A Matsuyama. Koji molds for Japanese soy sauce brewing: Characteristics and key enzymes. J Fungi (Basel) 2021. [Google Scholar]

- B Arulrajah, BJ Muhialdina, M Zarei, H Hasan, N Saar. Lacto-fermented Kenaf (Hibiscus cannabinus L.) seed protein as a source of bioactive peptides and their applications as natural preservatives. Food Control 2020. [Google Scholar]

- ME Kasimin, S Shamsuddin, AM Molujin. Enterocin: Promising Biopreservative Produced by Enterococcus sp. Microorganisms 2022. [Google Scholar]

- FJ Martí-Quijal, S Khubber, F Remize, I Tomasevic, E Roselló-Soto, FJ Barba. Obtaining Antioxidants and Natural Preservatives from Food By-Products through Fermentation: A Review. Fermentation 2021. [Google Scholar]

- C Dufresne, E Farnworth. Tea, Kombucha, and health: a review. Food Res Int 2000. [Google Scholar]

- K Thakur, SK Tomar, S De. Lactic acid bacteria as a cell factory for riboflavin production. Microb Biotechnol 2016. [Google Scholar]

- R Chu, R Li, C Wang, R Ban. Production of vitamin B2 (riboflavin) by Bacillus subtilis. J Chem Technol Biotechnol 2022. [Google Scholar] [Crossref]

- L Thomas, C Larroche, A Pandey. Current developments in solid-state fermentation. Biochem Eng J 2013. [Google Scholar]

- T Pan, Z Wang, JH Xu, Z Wu, H Qi. Extractive fermentation in cloud point system for lipase production by Serratia marcescens ECU1010. Appl Microbiol Biotechnol 2010. [Google Scholar]

- D Sharma, BK Kumbhar, AK Verma, L Tewari. Optimization of critical growth parameters for enhancing extracellular lipase production by alkalophilic Bacillus sp. Biocatalysis Agr Biotechnol 2014. [Google Scholar]

- J Babu, PW Babu, PA Kumar. Studies on the enhanced production of extracellular lipase by Staphylococcus epidermidis. J Gen Appl Microbiol 2006. [Google Scholar]

- AI Adetunji, AO Olaniran. Optimization of culture conditions for enhanced lipase production by an indigenous Bacillus aryabhattai SE3-PB using response surface methodology. Biotechnol Biotechnol Equip 2018. [Google Scholar]

- E Mobarak-Qamsari, R Kasra-Kermanshahi, Z Moosavi-Nejad. Isolation and identification of a novel, lipase-producing bacterium, Pseudomnas aeruginosa KM110. Iran J Microbiol 2011. [Google Scholar]

- S Sadhu, TK Maiti. Cellulase production by bacteria: a review. Br Microbiol Res J 2013. [Google Scholar]

- S Acharya, A Chaudhary. Bioprospecting thermophiles for cellulase production: a review. Braz J Microbiol 2012. [Google Scholar]

- PR Waghmare, SM Patil, SL Jadhav, BH Jeon, SP Govindwar. Utilization of agricultural waste biomass by cellulolytic isolate Enterobacter sp. SUK-Bio. Agr Nat Res 2018. [Google Scholar]

- SCB Gopinath, P Anbu, MKM Arshad, T Lakshmipriya, CH Voon, U Hashim. Biotechnological processes in microbial amylase production. Biomed Res Int 2017. [Google Scholar] [Crossref]

- RK Das, SK Brar, M Verma. Valorization of egg shell biowaste and brewery wastewater for the enhanced production of fumaric acid. Waste Biomass Valor 2015. [Google Scholar]

- A Chirapart, J Praiboon, P Puangsombat, C Pattanapon, N Nunraksa. Chemical composition and ethanol production potential of Thai seaweed species. J Appl Phycol 2014. [Google Scholar]

- Peyman Fasahati. Potential of brown algae for sustainable electricity production through anaerobic digestion. Energy Conversion Manag 2017. [Google Scholar]

- O Choi, Y Um, BI Sang. Butyrate production enhancement by Clostridium tyrobutyricum using electron mediators and a cathodic electron donor. Biotechnol Bioeng 2012. [Google Scholar]

- O Choi, T Kim, HM Woo, Y Um. Electricity-driven metabolic shift through direct electron uptake by electroactive heterotroph Clostridium pasteurianum. Sci Rep 2014. [Google Scholar] [Crossref]

- Y Jiang, HD May, L Lu, P Liang, X Huang, ZJ Ren. Carbon dioxide and organic waste valorization by microbial electrosynthesis and electro-fermentation. Water Res 2019. [Google Scholar]

- SS Yazdani, R Gonzalez. Anaerobic fermentation of glycerol: a path to economic viability for the biofuels industry. Curr Opin Biotechnol 2007. [Google Scholar]

- R Gallardo, MM Alves, LR Rodrigues. Modulation of crude glycerol fermentation by Clostridium pasteurianum DSM 525 towards the production of butanol. Biomass Bioenergy 2014. [Google Scholar]

- A Kujawska. ABE fermentation products recovery methods—A review. Renewable Sustainable Energy Rev 2015. [Google Scholar]

- AP Mariano, MJ Keshtkar, DIP Atala, F Maugeri, MRW Maciel, R Maciel. Energy requirements for butanol recovery using the flash fermentation technology. Energy Fuels 2011. [Google Scholar]

- M Uchida, T Miyoshi, M Kaneniwa, K Ishihara, Y Nakashimada, N Urano. Production of 16.5% v/v ethanol from seagrass seeds. J Biosci Bioeng 2014. [Google Scholar]

- B Pratto, MSR Dos Santos-Rocha, AA Longati, RS Júnior, AJG Cruz. Experimental optimization and techno-economic analysis of bioethanol production by simultaneous saccharification and fermentation process using sugarcane straw. Bioresour Technol 2020. [Google Scholar] [Crossref]

- WA Cavalcante, RC Leitão, TA Gehring, LT Angenent, ST Santaella. Anaerobic fermentation for n-caproic acid production: A review. Proc Biochem 2017. [Google Scholar]

- X Zhu, Y Zhou, Y Wang, T Wu, X Li, D Li. Production of high-concentration n-caproic acid from lactate through fermentation using a newly isolated Ruminococcaceae bacterium CPB6. Biotechnol Biofuels 2017. [Google Scholar]

- J Chwialkowska, A Duber, R Zagrodnik, F Walkiewicz, M Łężyk, P Oleskowicz-Popiel. Caproic acid production from acid whey via open culture fermentation-Evaluation of the role of electron donors and downstream processing. Bioresour Technol 2019. [Google Scholar]

- SV Bhat, R Akhtar, T Amin. An overview on the biological production of vinegar. Int J Fermented Foods 2014. [Google Scholar]

- MJ Torija, MDC García-Parrilla, AM Troncoso. Acetic acid bacteria and the production and quality of wine vinegar. Sci World J 2014. [Google Scholar] [Crossref]

- Yi-Liang Li, H Vali, J Yang, TJ Phelps, CL Zhang. Reduction of iron oxides enhanced by a sulfate-reducing bacterium and biogenic H2S. Geomicrobiol J 2006. [Google Scholar]

- Y Zhou, Y Gao, Q Xie, J Wang, Z Yue, L Wei. Reduction and transformation of nanomagnetite and nanomaghemite by a sulfate-reducing bacterium. Geochem Cosmochem Acta 2019. [Google Scholar]

- NI Chistyakova, VS Rusakov, DG Zavarzina, AI Slobodkin, TV Gorohova. Mössbauer study of magnetite formation by iron-and sulfate-reducing bacteria. Hyperfine Interact 2004. [Google Scholar]

- TH Austin, CF Pickett. The Decomposition of Hydrogen Sulphide. J Phys Chem 2002. [Google Scholar]

- J Galuszka, M De Falco,, L Marrelli, G Iaquaniello. Membrane-Assisted Catalytic Cracking of Hydrogen Sulphide (H2S). Membrane Reactors for Hydrogen Production Processes 2011. [Google Scholar]

- V Preethi, S Kanmani. Performance of nano photocatalysts for the recovery of hydrogen and sulphur from sulphide containing wastewater. Int J Hydrogen Energy 2018. [Google Scholar]

- Introduction

- Fermentation of South Indian Foods

- Biopreservation and Enhanced Taste of Food Products by Fermentation

- Anti Oxidants Obtained by Fermentation

- Vitamins Production

- Industrial Enzymes Produced by Fermentation

- Fermentation of Sea Weeds

- Electro Fermentation of Carbon Di Oxide and Organic Wastes

- Anaerobic Fermentation of Glycerol

- ABE Products

- N-caproic Acid Production

- Production of Acetic Acid & Vinegar

- Biogenic H2S & Nano Magnetite Mineral

- Conclusion & Future Aspects

- Source of Funding

- Conflict of Interest

How to Cite This Article

Vancouver

Meena P, Manimekalan A, T R, Moranga OM. Food fuel and fermentation products [Internet]. Indian J Microbiol Res. 2022 [cited 2025 Sep 13];9(3):164-170. Available from: https://doi.org/10.18231/j.ijmr.2022.030

APA

Meena, P., Manimekalan, A., T, R., Moranga, O. M. (2022). Food fuel and fermentation products. Indian J Microbiol Res, 9(3), 164-170. https://doi.org/10.18231/j.ijmr.2022.030

MLA

Meena, Parthiban, Manimekalan, Arunchalam, T, Radhakrishnan, Moranga, Obebo Meshack. "Food fuel and fermentation products." Indian J Microbiol Res, vol. 9, no. 3, 2022, pp. 164-170. https://doi.org/10.18231/j.ijmr.2022.030

Chicago

Meena, P., Manimekalan, A., T, R., Moranga, O. M.. "Food fuel and fermentation products." Indian J Microbiol Res 9, no. 3 (2022): 164-170. https://doi.org/10.18231/j.ijmr.2022.030